The oil and gas industry strives daily to satisfy the rising global energy demands; these demands have led to an increase in drilling operations across both land and sea. Drilling operations; if not properly managed can result in environmental pollution and severe degradation of the natural flora and fauna of the land and public health. This is why oil and gas firms are legally and ethically required to source products and responsibly dispose of waste. To effectively manage drilling waste and ensure minimal environmental impact; the oil and gas industry must employ advanced solids control technologies.

At Integrated Oilfield Support Services, we understand our responsibility to preserve the earth for future generations and we are committed to achieving this by deploying innovative solids control services that combine precision engineering and expertise to guarantee you minimal waste, zero oil spills, 100% quality drilling fluid, and zero operational downtime in compliance with environmental and governmental regulations. Our advanced solids control techniques encourage recycling, responsible drilling, improved public health, and lower the risk of solids land and water contamination.

As a collective; Integrated Oilfield Support Services is committed to championing and fulfilling SDG12 “Sustainable Consumption and Production”; targeted at achieving the environmentally sound management of drilling fluids and oil and gas wastes throughout their life cycle. Our solids control services; substantially reduce carbon emissions and waste generation through proper fluids and solids management, spill reduction, recycling, and reuse. Solids control is important in building a sustainable future and community.

Here is how our solids control services ensure environmental preservation and minimal impact while drilling:

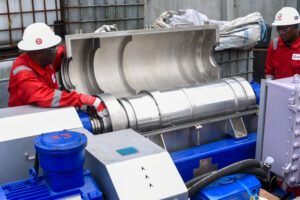

- We make use of Eco-friendly Cutting Edge Equipment: our vertical cutting dryers have a 0.2% Oil On Cutting (OOC) in comparison to our competition. This speaks to our efficiency and excellence

- Modern Equipment: our dual-purpose centrifuges can process low-gravity solids, high-gravity solids, and Barite recovery. It can also be modulated to a low-speed or high-speed regulation.

- In a bid to ensure zero spills, we use 16-inch conveyors. This helps prevent spillage and attests to our commitment to ensure reduced environmental hazards.

- Our solids control services comply with all regulations of all environmental regulatory agencies.

- Our solids control services enhance drilling efficiency resulting in fewer delays and less energy consumption, which in turn lowers carbon footprint, and reduces pollution and toxic emissions from drilling activities.

Are you interested in reducing your drilling operation’s carbon footprint?

Be proactive today and choose Integrated Oilfield Support Services for innovative and eco-friendly solids control services. We don’t just separate drill solids from drilling fluids and mud; we take a step further by ensuring that solids recirculated and discharged back into the environment are safe and hazard-free. Our Solids Control team is made up of experts and highly trained professionals ready to deliver innovative results.

Contact us via email at bdm@oilfieldsolutions-ng.com for more information.