For decades successful lifting operations in various industries like agriculture, maritime, construction, oil and gas; involved the use of specific and quality lifting accessories; like “Shackles”. Shackles are popular in industrial lifting operations, securing and rigging jobs. They are commonly used together with other lifting accessories like wire rope slings, webbing slings, cranes, etc., acting as the final link in a sling setup or connection chains.

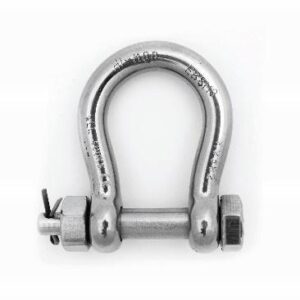

Shackles are U-shaped pieces of steel alloy with a pin on the open, non-curved part. They are important in the safe and efficient movement of load and equipment from place to place. Shackles come in different sizes and types of pins specific to different lifting needs.

Here are 7 amazing facts you didn’t know about shackles:

1. The earliest versions of shackles were made from wood, bone, or stone; this dates back to ancient times.

2. The ancient Greeks and Romans improved on the earlier versions and developed more sophisticated and durable shackles using bronze and iron. They used shackles for securing cargo and anchors.

3. The word shackle originates from an Old English word “sceacel” or “scacol” which means to bond or fetter.

4. Shackles are designed to withstand harsh temperatures and corrosion. Notwithstanding the durable nature of Shackle; it is crucial to properly maintain and inspect shackles before use to ensure safety.

5. Shackles have a Working Load Limit (WLL) and a Maximum Breaking Load (MBL). This is why it is advised against overload and using the right size of shackle for any lifting operation.

6. There are two main classifications of shackles namely, Anchor shackles (also known as Bow shackles) and D-shackles. D-shackles are commonly used for straight-lifting operations and Anchor shackles are used in multiple sling-leg connections and angular lifting. Both Anchor and D-shackles are commonly coupled with either a screw, screw pin, safety pin or bolt and nut.

7. Shackles are tested and certified to meet the following international standards, ASME and EN. The ASME B30. 26 requires shackle manufacturers to have identification markings on the shackle body and the shackle pin.

Shackles are essential lifting gears that have various uses across several industries. They perform a great feat in enhancing lifting operations, efficient safe handling of load and are durable enough to stand the test of time.

Are you interested in purchasing quality Anchor shackles or D-shackles for lifting construction beams or rigging materials?

Integrated Oilfield Support Services is the number 1 lifting gear supplier in West Africa. We have a variety of quality shackles and lifting gears specially fabricated to meet all your lifting operations. Our lifting gears are certified, tested, trusted and guaranteed to surpass your expectations. Contact us today at delivery@iossafrica.com to place an order.